Quadratec Part #:

97017-1801

ARB Part #:

AR32SV2

Description

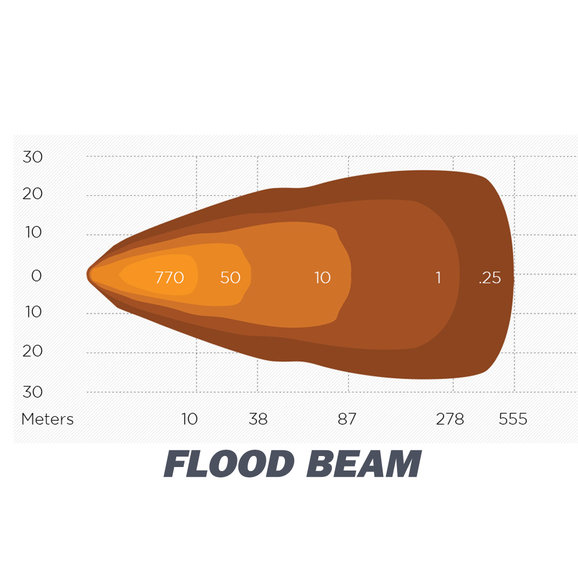

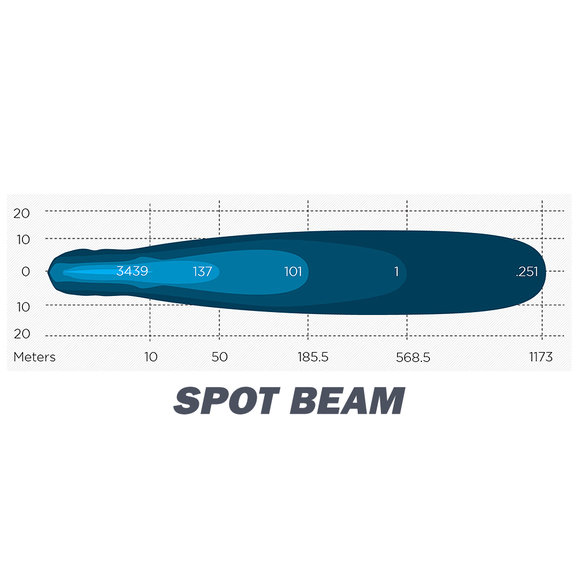

ARB set out to design the Intensity AR32 series to compete with light bars that have rapidly gained popularity in the off-road community. ARB offers the AR32 in a flood beam configuration to illuminate everything immediately within the driver’s field of view and provide quality light for slower off-road driving. A spot beam configuration is also available granting the driver the ability to see greater distances. This reduces fatigue because the driver will not need to strain to see beyond the edge of the beam. Equipped with 32 LEDs, the ARB Intensity spot and flood beams are capable of producing 8200 raw Lumens and have a color temperature of 6500K making them as close to daylight as possible. The cast aluminum body is lightweight and great for cooling ultimately increasing the efficiency and prolonging the life of the LEDs. The body is finished in a textured polyester powder coat that stands up to road grime, salt, and UV rays. The TIG-welded 304 stainless steel mounting system is designed to stand up to the harshest conditions and underwent military-spec vibration testing. ARB uses 304 stainless for superior strength and exceptional corrosion resistance. Other durable features include a molded rubber seal that keeps out dust and water, a virtually unbreakable and scratch-resistant polycarbonate lens, and a 50,000 hour LED lifespan.

Popular Similar Items

Details

Flood and Spot Beam Versions Available For Different Driving Environments and Conditions.

Durable Components Include Lightweight Cast Aluminum Body, Polyester Powder Coat, 304 Stainless Steel Bracket, and Virtually Unbreakable Polycarbonate Lens

Technical Specs:

- 32 LEDs

- 8200 Raw Lumens

- 6500K Color Temperature

- Dimensions: 9.7in T x 8.7in W x 4.7in D

- 20° Full Width Flood

- 10° Full Width Spot

- 10-36 V DC Input

- 90 Watts

- Amp Draw 6.25A @ 14.4V

- Operating Temp: -40°F to +145°F

- Submersible Up To 9.8ft

- 50,000 Hour LED Lifespan

- Light Pattern: Spot

- Lighting Type: Round

ARB Intensity AR32 9.5" LED Driving Light Options

| Part Number | Catalog # | Price | |||||||

|---|---|---|---|---|---|---|---|---|---|

| AR32SV2 | 97017-1801 | Spot Beam Pattern | $844.00 |

Share Your Thoughts

- Shared By Others

- Share a Photo

- Ask a Question

- Write a Review