This short shaft kit, or slip yoke eliminator, with the new, heavy duty shaft is engineered to withstand the increased torque (50% increase) generated by extreme reduction of the Tera Low231. The kit also eliminates the need to lower the transfer case in most cases by increasing the rear driveshaft length by four inches. It includes a larger output bearing and rear housing.

Note: Requires a longer CV driveshaft, which is sold separate

SLIP YOKE ELIMINATORS - 101

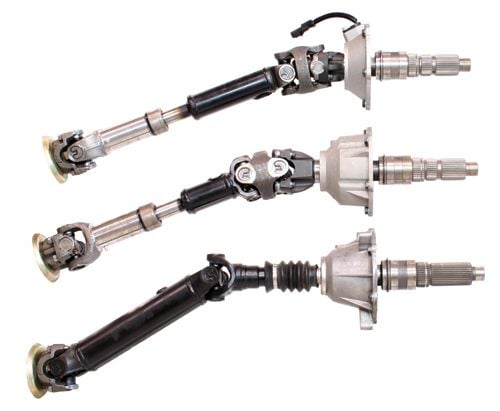

Most 231 transfer cases came from the factory with a slip-yoke rear output (see bottom photo). This slip yoke will slide or slip in and out of the rear of the transfer case as the suspension cycles up & down. When driveshaft angles are changed due to suspension height or suspension travel the slip yoke is forced to operate at an angle and can cause binding, and in some situations will crack the case.

Another problem with the slip yoke design is that the rear driveshaft yoke cannot be removed from the vehicle without loss of transfer case fluid.

Broken u-joints can often require the vehicle to be driven back off the trail with the front driveshaft only. Without eliminating the slip yoke on the

rear output, this would be impossible without losing the transfer case fluid, and causing transfer case damage.

On any short wheel base vehicle (such as the Wrangler), driveshaft angle is very critical and

must be addressed when making any suspension modifications. Standard factory Wrangler

driveshafts are about 12. This short driveshaft will cause severe vibration and premature u-joint failure if not upgraded.

A Short Shaft kit, or Slip Yoke Eliminator solves the short driveshaft length, allows driveshaft removal in the event of a u-joint failure without loss of fluid, and increases the output shaft strength dramatically allowing for increased

power and torque to be transferred to the wheels for traction.

There are several approaches to Slip Yoke Eliminator kits. Some use a hack & tap' method which results in a lower priced kit, but does not effectively increase any strength, and can actually increase driveshaft vibration. TeraFlex was one of the innovators that developed a completely new heavy duty output shaft that can increase

torque loads by nearly 50%, as well as offer solutions to the original slip yoke problems. TeraFlex has perfected low range gearing and continues to lead the industry in quality performance transfer case products.

Top Photo: Extreme Short Shaft SYE

Middle Photo: Standard Short Shaft SYE

Bottom Photo: Stock Slip-Yoke

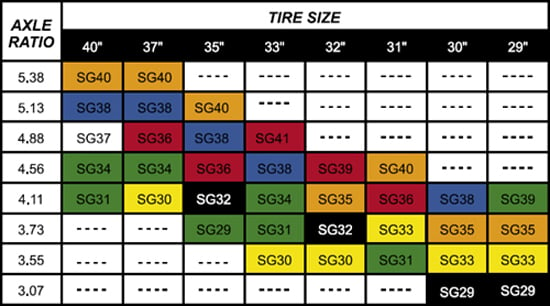

Changing your ring and pinion ratio and/or tire size will cause an inaccurate

reading of your speedometer. Replacement of the speedometer gear is a simple

procedure that takes minutes to complete. The chart below lists ring and pinion

ratios and tire size. Simply select the proper configuration of your vehicle from the

chart.

An accurate speedometer reading is important both on and off road when detailing

travel routes and for on highway safety.

Factory speedometer variances are ±3% from actual speed. Recommended

speedometer driven gears are based on a manufacturer's published tire specs for

revolutions per mile. This may differ from manufacturer to manufacturer.

Standard Short ShaftSpeedometer Gear Chart

Fits 231-J transfer cases only

Earlier 231 applications with mechanical speedometer cable require updating to an electronic speedometer.

Output Shaft

Output Housing

Yoke and Nut

Installation Hardware

- Transfer Case Model: NP231

- Shipping Weight: 16lb

- Shipping Dimensions: 17in x 13in x 6in (L x W x H)

Jeep Wrangler (TJ)

- 2006 Jeep Wrangler (TJ)

- 2005 Jeep Wrangler (TJ)

- 2004 Jeep Wrangler (TJ)

- 2003 Jeep Wrangler (TJ)

- 2002 Jeep Wrangler (TJ)

- 2001 Jeep Wrangler (TJ)

- 2000 Jeep Wrangler (TJ)

- 1999 Jeep Wrangler (TJ)

- 1998 Jeep Wrangler (TJ)

- 1997 Jeep Wrangler (TJ)

Jeep Wrangler (YJ)

- 1995 Jeep Wrangler (YJ)

- 1994 Jeep Wrangler (YJ)

- 1993 Jeep Wrangler (YJ)

- 1992 Jeep Wrangler (YJ)

- 1991 Jeep Wrangler (YJ)

- 1990 Jeep Wrangler (YJ)

- 1989 Jeep Wrangler (YJ)

- 1988 Jeep Wrangler (YJ)

- 1987 Jeep Wrangler (YJ)

Jeep Wrangler Unlimited (LJ)

- 2006 Jeep Wrangler Unlimited (LJ)

- 2005 Jeep Wrangler Unlimited (LJ)

- 2004 Jeep Wrangler Unlimited (LJ)

- Shared By Others

- Share a Photo

- Ask a Question

- Write a Review

Teraflex 231 Short Shaft Kit Reviews

Bought my ‘92 Wrangler to rebuild and it was bad. Found out that the inner transfer case shaft was bent and so this new SYE kit was the answer. No more leaks and with the new Tom Woods drive shaft no vibration and super solid drive train now. Well worth the work to not have those worries on the trail. Great upgrade!

Fits perfectly

Works very well and not difficult at all to install