by: Torque Staff Report

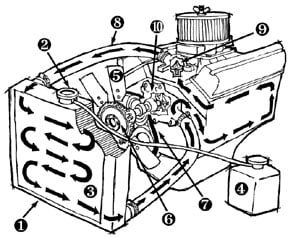

1) Radiator - The radiator is responsible for the transferal of heat from the circulating coolant to the air passing through it. Heated coolant flows into the top of the radiator from the engine. The coolant is passed through a series of tubes and fins that effectively dissipate the heat in the coolant. Heated coolant flows into the top of the radiator from the engine. The coolant is passed through a series of tubes and fins that effectively dissipate the heat in the coolant.

2) Radiator Cap - Modern radiator caps are technically pressure valves. These are responsible for regulating pressure inside of the cooling system and allowing it to increase. Increasing the cooling system pressure raises the boiling point of the coolant. For every additional pound of pressure, the coolant's boiling point increases by 3ºF. General rates of increase are usually 8psi to 15psi. If pressures exceed the rated amount for the cap, the valve will open and release the pressure and possibly coolant as well. This coolant will be highly susceptible to flash boiling. DO NOT come in contact with it! 3) Coolant - As coolant flows through the hot engine, it transfers heat to the radiator fins, which in turn transfers it to the passing air. In addition to providing improved performance over plain water, most leading antifreeze products contain anti-rust and anti-corrosion additives that prevent sediment buildup and premature cooling system component failure. 4) Coolant Recovery Tank - The coolant recovery tank serves as a reservoir. It receives coolant expelled from the cooling system as the system cools down. It holds the expelled coolant for reintroduction into the cooling system when needed. When additional coolant is needed in the system, it should be added to the recovery tank, not directly to the radiator. 5) Fan - This system can be either mechanical, electrical or a combination of both. The fan, depending on design, will push or pull cooler air through the radiator to aid heat transfer from the coolant. 6) Fan Clutch - The fan clutch is used on mechanical fans only. It is designed to keep the optimum amount of air flowing through the radiator. At slow vehicle speeds, the fan is required to move enough air through the radiator to ensure proper cooling. At highway speeds, the airflow through the radiator is sufficient to provide proper cooling without the aid of the fan. The clutch lets the fan free-wheel at highway speeds, reducing power loss and helping to increase fuel economy. 7) Belts - Serpentine belts, v belts, and v-ribbed belts are all used designs. Serpentine belts are the most commonly used belts in today's vehicles. The belt(s) is/are responsible for driving the water pump, along with other accessories while the engine is running. It is directly connected to the crankshaft via a crankshaft pulley. Always check your belts for proper adjustment and make sure they are not cracked, excessively worn, or slipping. Be mindful to never over-tighten belts. An over-tightened belt can put unnecessary side-load pressures on the water pump impeller shaft, bearings and other accessories. This could also lead to premature failure . 8) Hoses - Radiator hoses are responsible for carrying coolant to the engine from the radiator and back again. They should be checked regularly for signs of deterioration, such as bulging and cracking. Healthy hoses should be pliable, not soft and spongy or hard and brittle. Any sign of leakage could mean that it's time for a replacement. 9) Thermostat - The thermostat is responsible for regulating the flow of coolant to the radiator. It keeps the engine block at its optimum operating temperature. When the engine is cold, the thermostat closes to restrict coolant flow to the radiator and allow the engine to quickly reach its operating temperature. As the engine heats up, the thermostat opens and allows coolant to circulate throughout the entire coolant system. The thermostat can fail by either sticking open, sticking closed, or completely breaking and causing an internal blockage. All these scenarios can cause overheating, no hot air output, or low running temps. 10) Water Pump - The water pump is the main drive of the coolant system. It keeps the coolant in a continuous flow from the engine block to the radiator and all points in between. There are various designs of the impeller, but the most common design seen is a paddle style. The impeller rotates on a bearing-supported shaft and is driven externally by a pulley/belt combination connected to the crankshaft pulley. Keeping the coolant clean and the serpentine belt properly tensioned is about all the maintenance the water pump requires. |