Torque Staff Report

What This Guide Covers

- 5-lug bolt patterns by Jeep model year

- Proper lug-nut torque settings

- Measuring methods

- Installation checklist

- Common mistakes to avoid

Why It Matters

When upgrading your Jeep Wheels, whether for style, performance, or a lift kit, ensuring you match the correct bolt pattern and apply the right lug-nut torque is crucial for safety, performance and legal fitment. Mismatched wheels can lead to vibration, premature wear, or, worse, wheel separation. Now, you may know the wheel size you need thanks to your tires, but the bolt pattern is a different story. That's because, while most Jeep Wheels have five lug nuts, different models have different lug-nut spacings. For example, all JK Wrangler vehicles (2007-18) have a 5x5 bolt pattern—meaning five lugs with a 5-inch spacing. Earlier TJ Wrangler models (1997-06) and YJ editions (1987-95) employ a 5x4.5 pattern. Other Jeeps may use different lug setups, so our Jeep-specific chart below breaks down vehicle year/model and bolt pattern to help you decide which one exactly represents your vehicle.

Common Jeep Wheel Bolt Patterns

| Vehicle/Year Ranges | OEM Wheel Size | Lug Pattern | Stud Size | Hub Center Bore |

| 2020-24 Jeep Gladiator JT | 17" - 18" | 5 on 5 | 14mm x 1.50 | 71.5 |

| 18 - 25 Jeep Wrangler JL | 17" - 18" | 5 on 5 | 14mm x 1.50 | 71.5 |

| 07 - 18 Jeep Wrangler JK | 17" - 18" | 5 on 5 | 1/2 x 20 | 71.5 |

| 97 - 06 Jeep Wrangler TJ | 15" - 16" | 5 on 4.5 | 1/2 x 20 | 71.5 |

| 87 - 95 Jeep Wrangler YJ | 15" - 16" | 5 on 4.5 | 1/2 x 20 | 71.5 |

| 41 - 86 Jeep MB & CJ Series | 15" | 5 on 5.5 | 1/2 x 20 | 108 |

| 84 - 01 Jeep Cherokee XJ & Commanche MJ | 15" | 5 on 4.5 | 1/2 x 20 | 71.5 |

| 93 - 98 Jeep Grand Cherokee ZJ | 15" | 5 on 4.5 | 1/2 x 20 | 71.5 |

| 99 - 04 Jeep Grand Cherokee WJ | 16" - 20" | 5 on 5 | 1/2 x 20 | 71.5 |

| 05 - 10 Jeep Grand Cherokee WK | 16" - 20" | 5 on 5 | 1/2 x 20 | 71.5 |

| 11 - 19 Jeep Grand Cherokee WK2 | 16" - 20" | 5 on 5 | 14mm x 150 | 71.5 |

| 14 - 19 Jeep Cherokee KL | 17" - 18" | 5 x 110(metric) | 12mm x 1.25 | 65.1 |

| 06 - 10 Jeep Commander XK | 17" - 18" | 5 on 5 | 1/2 x 20 | 71.5 |

| 02 - 12 Jeep Liberty KJ/KK | 16" - 18" | 5 x 4.5 | 1/2 x 20 | 71.5 |

| 07 - 16 Jeep Compass, Patriot | 17" - 18" | 5 on 4.5 | 12 x 1.5 | 67.1 |

| 62 - 73 Jeep J Series & Full Size Wagoneer | 15" | 5 x 5.5 | 1/2 x 20 | 108 |

| 74 - 91 Jeep J Series & Full Size Wagoneer | 15" | 6 on 5.5 | 7/16 | 108 |

If your Jeep is modified (lift, tires, aftermarket axles), always verify the actual bolt pattern and hub bore before ordering wheels.

How to Measure Your Bolt Pattern

Now that you understand bolt patterns, you may be unsure what type of Jeep you have or even its model year. So, rather than go on an exhaustive trek to get that information, simply measure that lug pattern size.

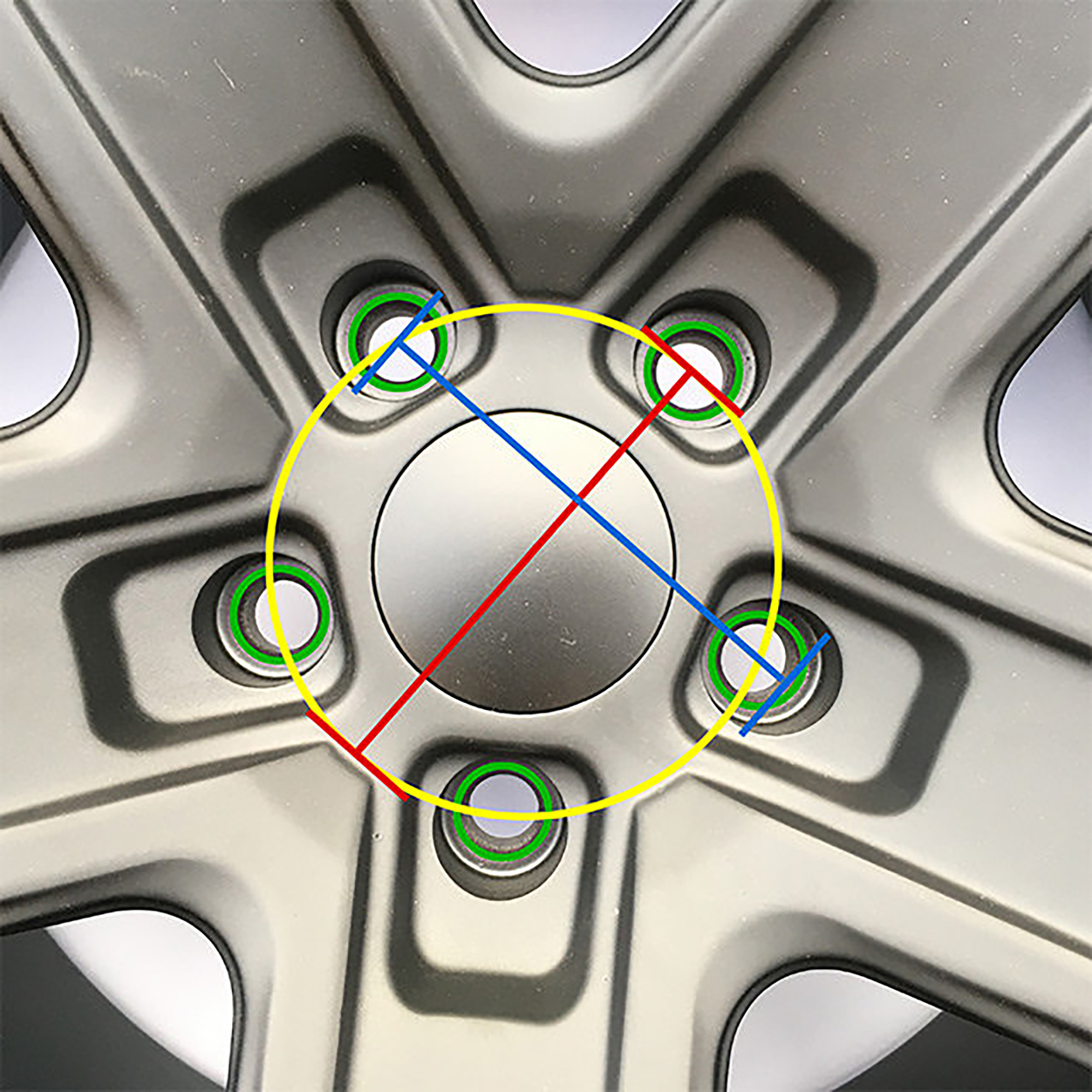

First, count the lug bolt holes. On a Jeep, you normally have five lug nuts, which makes measuring a bit tricky, but not difficult. You need to measure the bolt pattern circle (the yellow circle on the diagram below). To do that, pick any bolt hole to start from, align your ruler at the outermost edge of the hole, then skip one bolt hole and measure to the center of the next adjacent hole (as indicated by the blue line in the diagram). That will give you your bolt pattern circle diameter (the yellow circle on the diagram). This wheel has five holes, and when we measured the bolt pattern circle diameter, it was 4.5 inches. So, we would say the bolt pattern is 5 on 4.5 or 5x4.5.

How to Properly Torque Lug Nuts

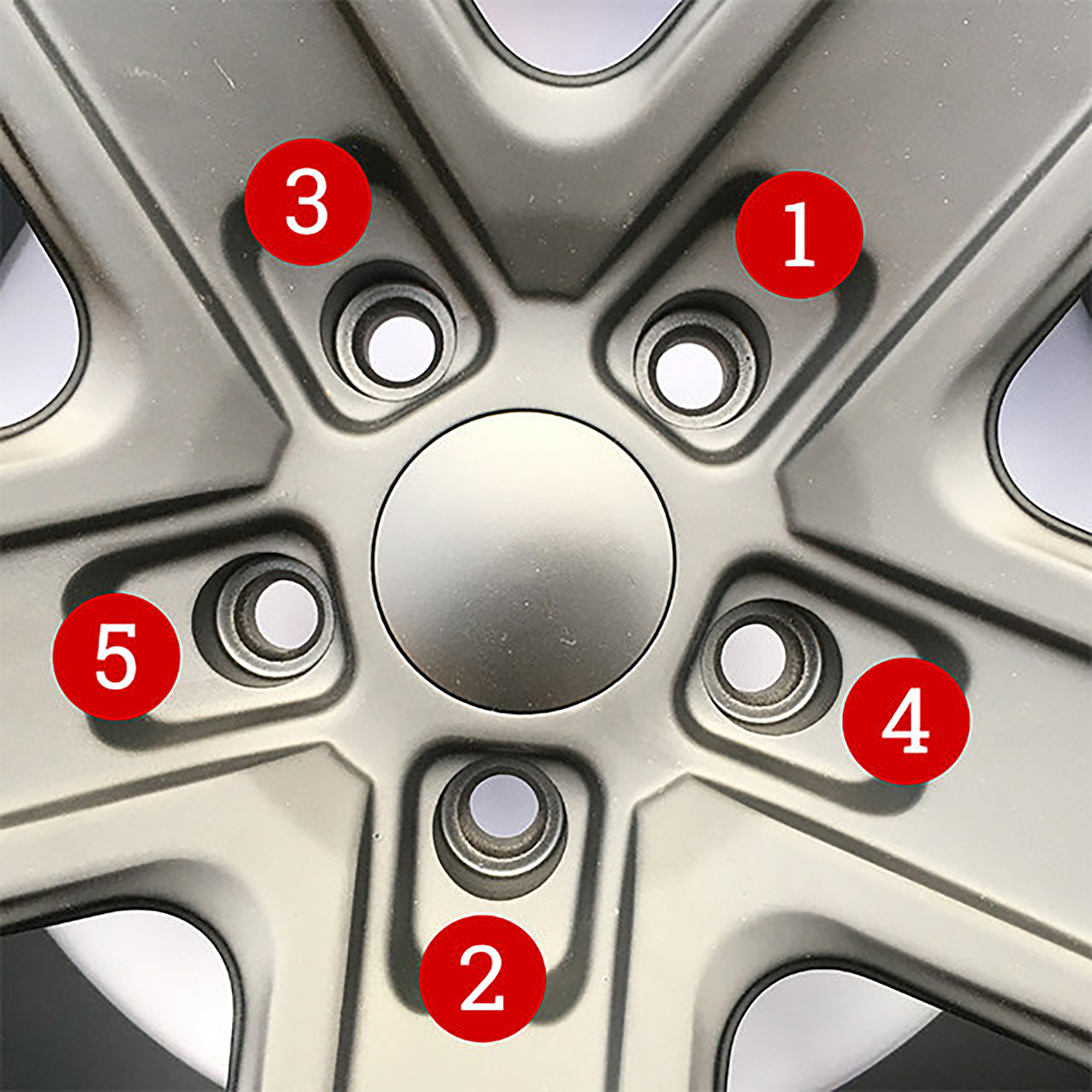

Making sure those lug nuts are snug once the wheels attach isn't just lip service. It is crucial to ensure proper safety when operating your Jeep. So, once those wheels are on, start by using a good lug wrench like the Gorilla Power Lug Wrench and tighten the first lug to its proper torque (the exact torque for your vehicle can be found in your owner's manual). Then, move to the lug nut adjacent to the one you tightened. Next, move back across the wheel again. Follow the pattern shown in the diagram below, working back and forth across the wheel until all lug nuts have been properly torqued. If you know your lug size but do not have an owner's manual, you can use our lug nut torque chart to set the proper torque. One thing to remember: never over-torque those lugs. Make sure you know the proper torque spec for your vehicle, as over-torqued lug nuts can shear off and could cause you to lose control of the Jeep.

Typical Jeep Lug-Nut Torque Specifications

| Lug Size | Ft/Lbs Torque |

| 7/16" | 55-65 |

| 1/2" | 75-85 |

| 9/16" | 95-115 |

| 5/8" | 135-145 |

| 12mm | 72-80 |

| 14mm | 85-95 |

Offset & Fitment Checklist (for New Wheels)

- Ensure bolt pattern matches exactly

- Confirm hub bore or select hub-centering rings

- Check offset/backspacing: wheels pushed too far outward or inward can rub or cause clearance issues

- Torque lug-nuts properly and retighten after initial use

- Use quality tools: calibrated torque wrench and impact wrench if available

- If modifying (lift kit, larger tires), verify new specifications for suspension and axle load

Common Mistakes & How to Avoid Them

- Installing Jeep Wheels with an incorrect bolt pattern or hub bore can result in vibration, uneven wear

- Over-torquing lug-nuts may cause stud failure or stripped threads

- Using stock torque for aftermarket wheels without adjusting for size or material difference.

- Ignoring retightening after initial miles.

- Forgetting to check local fender-coverage laws if wheels extend beyond the body.

Frequently Asked Questions

Q: My torque spec is 75 ft-lbs, but after a lift kit I should use higher, right?

No. Always follow wheel and hardware manufacturer specs. Modifications don’t necessarily increase torque requirements.

Q: Can I use 5×4.5″ wheels on my 5×5″ JK?

No. Even a small mismatch can lead to poor seating and dangerous vibration or failure.

Q: Do I need a hub-centric or lug-centric wheel?

Hub-centric wheels center themselves on the axle bore and are preferred. If you use lug-centric wheels on a modified Jeep, consider hub-centric spacers.